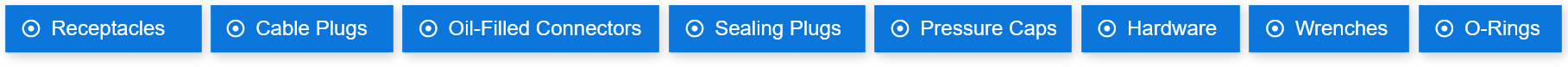

Deepsea Connectors

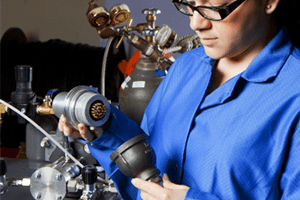

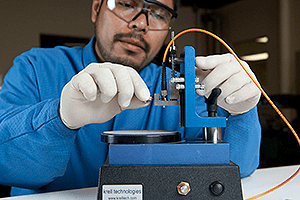

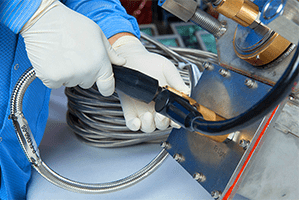

CONNECTORS, CABLES & PENETRATORS

BIRNS invests in new certifications, ground-breaking testing equipment and advanced manufacturing techniques to deliver the industry’s most sophisticated high-performance subsea connectors and cable assemblies.

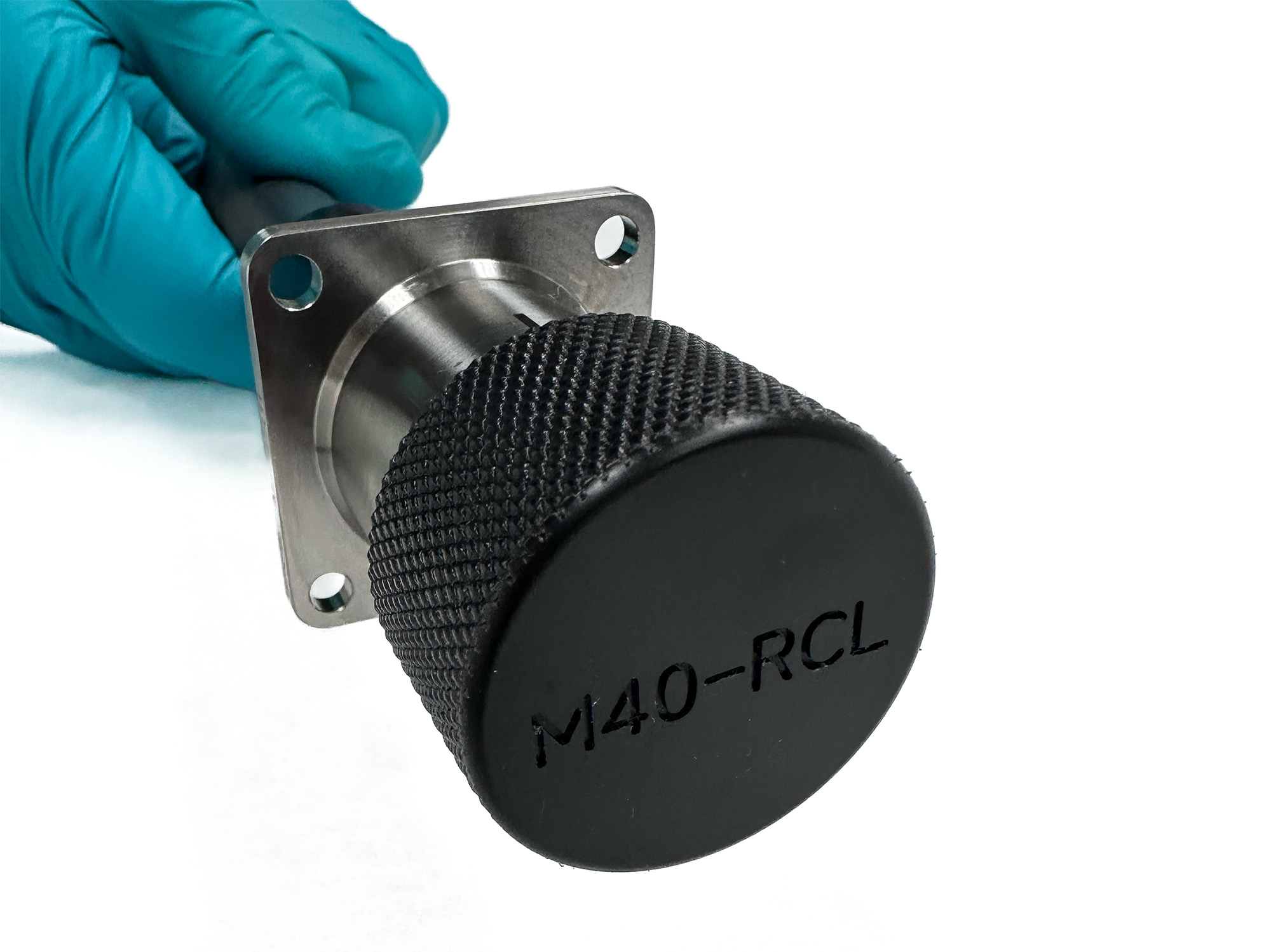

UNDERWATER LIGHTING

UNDERWATER CHAMBER & FLOODLIGHTING

BIRNS underwater lighting is used in a variety of applications from divers to diving bells, submarines, ROVs and more throughout the world due to extremely rugged designs – proven to perform in the harshest subsea environments.

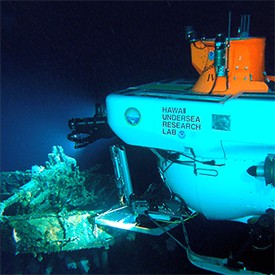

Nuclear Lighting

EMERGENCY LIGHTS & UNDERWATER LIGHTING

BIRNS proven nuclear facility lighting solutions are the industry’s most advanced–from underwater camera lights, reactor core fueling lights and fuel pool lights, to seismically qualified UL-listed emergency and high bay lights.